How Regular Welding Inspection Madison Can Conserve You Time and Money

How Regular Welding Inspection Madison Can Conserve You Time and Money

Blog Article

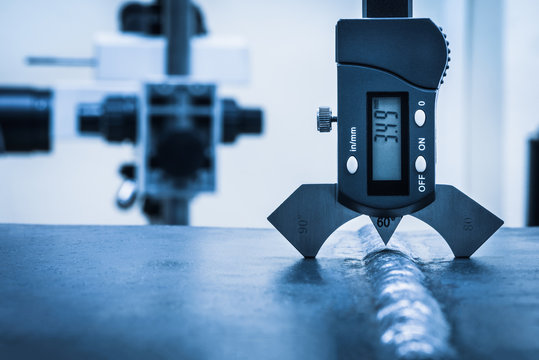

Exploring Advanced Tools and Techniques for Accurate Welding Evaluation

In the world of welding inspection, the search of accuracy and integrity is vital, stimulating the growth of advanced devices and approaches. Laser scanning advancements and automated inspection systems, outfitted with fabricated intelligence, are redefining the landscape by lowering human mistake and enhancing safety procedures.

Ultrasonic Checking Technologies

Ultrasonic testing developments regularly represent the center of advancements in welding examination technologies. These advancements have actually considerably boosted the ability to spot and review suspensions within bonded structures, ensuring boosted integrity and safety.

Additionally, innovations in software program formulas for information analysis have actually enhanced the precision of defect detection and sizing. Automated ultrasonic screening systems currently offer high-resolution imaging, making it possible for in-depth assessments of weld top quality. These systems are usually incorporated with sophisticated visualization tools, which promote the analysis of results.

Radiographic Inspection Techniques

While ultrasonic testing innovations have actually established a high criterion in non-destructive exam, radiographic examination techniques remain to play an essential duty in welding evaluation by using special insights right into product stability. Radiographic testing (RT) utilizes using X-rays or gamma rays to penetrate materials, creating a radiograph that visually stands for the inner framework of a weld. This imaging capability is indispensable for spotting subsurface flaws such as porosity, inclusions, and splits that may not show up through surface assessments.

The procedure involves placing a radiation resource on one side of the weld and a detector on the opposite side. Variants in material density and thickness impact the depletion of the rays, generating a different image that precisely defines imperfections. RT is especially helpful for inspecting complex geometries and thick areas where various other approaches may drop brief.

Regardless of its performance, radiographic evaluation must be carried out with strict adherence to security methods due to the dangerous nature of ionizing radiation. In addition, the analysis of radiographs calls for experienced employees, as the quality of the evaluation directly impacts the integrity of the assessment. As a result, continuous innovations in electronic radiography are improving picture quality and analysis efficiency, strengthening RT's essential function in guaranteeing weld high quality.

Laser Scanning Breakthroughs

Accepting laser scanning innovation in welding examination has actually changed the assessment of weld quality and honesty. Unlike conventional examination methods, laser scanning supplies rapid information procurement, significantly boosting the performance and precision of weld analyses.

Laser scanning breakthroughs have actually brought about significant enhancements in defining and detecting surface area problems such as porosity, lack of combination, and damages. The high-resolution data allows assessors to carry out thorough analyses, making sure that welds meet rigorous sector requirements. This method sustains the growth of digital records, helping with long-lasting high quality guarantee and traceability.

Additionally, laser scanning technology incorporates effortlessly with software program remedies designed for automated problem detection and evaluation. The resultant data can be easily shared and evaluated, advertising collaborative decision-making processes. As sectors proceed to demand higher criteria for weld quality, laser scanning stays at the leading edge, using exceptional accuracy read this and performance in welding inspection.

Automated Inspection Solutions

Automated evaluation systems offer the benefit of uniformity, removing human mistake and subjectivity from the evaluation process. They are created to run in various settings, from manufacturing floorings to remote field sites, guaranteeing detailed coverage. Welding Inspection Madison. These systems can be set to abide by particular welding requirements and requirements, supplying comprehensive reports and paperwork for high quality control objectives

Additionally, the assimilation of cloud-based platforms assists in the storage and analysis of large quantities of inspection data. This allows trend analysis and anticipating maintenance, enabling makers to address potential problems prior to they intensify. The fostering of automated examination systems is a crucial step in the direction of boosting the reliability and efficiency of welding procedures in industrial applications.

Enhancing Safety And Security and Effectiveness

A substantial element of boosting security and effectiveness in welding inspection depends on the combination of innovative innovations that enhance procedures and mitigate dangers. The fostering of innovative non-destructive testing (NDT) approaches, such as ultrasonic testing, phased variety ultrasonic screening (PAUT), and radiographic testing, plays an essential function in making certain structural stability without endangering the safety of the personnel entailed. These techniques permit comprehensive assessments with minimal downtime, lowering possible dangers connected with traditional approaches.

Moreover, the execution of real-time information analytics and artificial intelligence algorithms has transformed the way examination data is analyzed. By employing anticipating analytics, possible problems can be determined before they show up into vital failings, making certain prompt interventions and upkeep. This proactive technique substantially enhances functional performance and safety in welding processes.

Moreover, remote inspection modern technologies, including drones and robot spiders geared up with high-resolution cameras, allow inspectors to assess hard-to-reach areas without revealing them to unsafe problems. This not only boosts inspection accuracy however likewise minimizes human danger. By leveraging these innovative tools and methods, industries can achieve higher safety standards and functional effectiveness, ultimately leading to more trusted and lasting welding examination methods.

Conclusion

The combination of innovative tools and approaches in welding assessment significantly boosts problem discovery Web Site and ensures structural stability. These innovations not just enhance examination performance yet likewise contribute to enhanced security and high quality assurance in industrial welding applications.

Ultrasonic testing developments often stand for the leading edge of advancements in welding examination modern technologies.While ultrasonic screening developments have actually set a high criterion in non-destructive assessment, radiographic evaluation methods continue to play an integral role in welding inspection by using special understandings into product stability.Accepting laser scanning innovation in welding inspection has revolutionized the assessment of weld quality and integrity. As industries continue to demand higher criteria for weld high quality, laser scanning remains at the forefront, using unmatched accuracy and efficiency in welding assessment.

Automated examination systems supply the benefit of consistency, removing human mistake and subjectivity from the inspection procedure.

Report this page